| Power generating mechanisms work most efficiently when

they operate within a relatively narrow range of speeds, while specific

power applications might require a broader range of speeds, e.g., electric

drill, motorcycle, lathe, chain saw. Drive gearing is used to bridge this

gap, ensuring the power is delivered efficiently but at the right speeds

for the application.

Traditional Gearing Waveform Gearing |

|

|

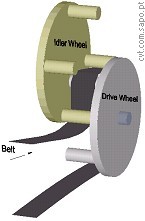

How Waveform Gearing Works Waveform gearing simply generates a wave in the path of a chain (or belt) transmission to increase its gearing. Refer drawing: The Input Drive engages the Idler Sprocket causing it to rotate counter clockwise. The meshing of these two sprockets is utilised to pull the chain between them following the waveform path of the sprocket teeth. |

| This in turn will cause the Final Drive Sprocket to rotate. The extent of tooth meshing of Drive Sprocket with Idler Sprocket determines the waveform amplitude (see below) and hence the distance travelled by the chain for each degree of rotation of Drive Sprocket. The effect of this is that the chain moves faster than its drive sprocket. | |

|

Waveform Gearing Mechanisms The waveform generation can be by many different mechanisms but all possessing the essential feature that they pass a power translation line (belt or chain) through a generated waveform path so as to increase its travel speed. An example is shown of a pinwheel driven mechanism. |